Chemical fume hoods provide protection from vapors, splashes, and impacts caused by chemicals and their reactions. However, fume hoods do not completely eliminate the hazards, they must be used correctly to minimize the chance of exposure.

Notes: Biological safety cabinets are not equivalent to chemical fume hoods and do not provide protection from hazardous vapors. Procedures in which perchloric acid is heated above ambient temperatures must be performed in a specialized fume hood equipped with a wash-down system.

Background

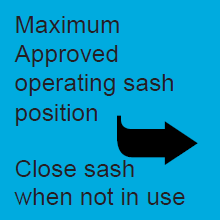

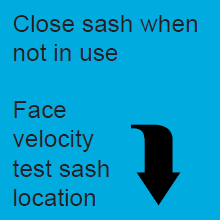

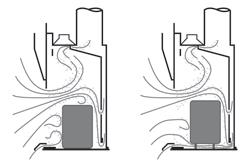

Chemical fume hoods are equipped with a fan in the duct work that generates air flow from the front to the back of the hood. Air escapes through slots or baffles at the back of the hood. The air flow captures vapors and prevents them from diffusing into the room. Hoods are designed so that the air velocity at the plane of the sash is optimal for capturing vapors when the sash opening is no greater than the maximum operating position (for vertical opening sashes) or the test opening (for horizontal opening sashes). For vertical sliding sashes, the maximum operating height of the sash is typically 18 inches; a larger opening limits the performance of the hood. The opening should be minimized on hoods with horizontal sliding sashes and the user should work with one sash directly in front of them with their arms on either side of the sash as shown in Figure 1 below. Maximum sash opening are identified using blue stickers shown below in Figure 2. On combination hoods that include both the vertical and horizontal sashes, it is best practice to put the vertical sash all the way down before opening and using the horizontal sashes. Opening the sash beyond the optimal position will dramatically lower the air velocity and allow vapors to escape into the room. Blocking the airflow with large equipment in the hood can also lead to insufficient vapor capture and potential exposure, as shown in Figure 3 below:

Figure 1: Proper use of a hood with horizontal sashes. Sash is between researcher and work being performed in the hood.

Figure 2: The blue arrow sticker on the left indicates the maximum operating height for a hood with a vertical sash (moves up and down).The blue arrow sticker on the right indicates teh sash test locations for hoods with horizontal sashes (moves side to side).

Figure 3: In the left image, the airflow to the bottom slot is blocked, allowing vapors to escape into the room. In the right image, air flows underneath the elevated equipment, improving efficiency of the hood.

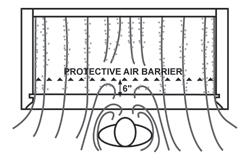

A person standing in front of the hood also disrupts the airflow, generating eddy currents. Vapors within those currents may escape into the room. Eddy currents drop off at about six inches into the hood.

Figure 4: Top view of air currents created when someone is working in front of a hood.

Hood Inspections

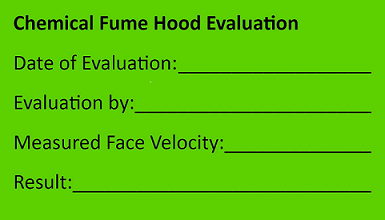

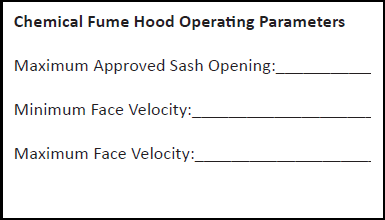

A campus-wide Chemical Fume Hood Surveillance Program is coordinated by the Occupational Safety and Health Department (OSH). Fume hood velocity is measured annually by OSH. If the velocity falls within the operating range established by the campus of 80 and 120 linear feet per minute (fpm), or within the operating range esbalished by the manufacturer and verified through as-installed containment testing, the hood will receive a green Chemical Fume Hood Evaluation tag bearing the date of the inspection as shown below in Figure 5. Approved operating flow range and maximum approved sash opening are listed on the white Chemical Fume Hood Operating Parameters sticker that is placed on teh fume hood and shown below in Figure 6.

Figure 5: Green CHemical Fume Hood Evaluation card indicating the face velocity was within corresponding operating flow range.

Figure 6: White Chemical Fume Hood Evaluation sticker.

If research work in your fume hoods is critical, the Facilities and Services (F&S) Sheet Metal Shop can provide annual testing and immediate repair by requesting a Preventative Maintenance work order through the F&S Service Office.

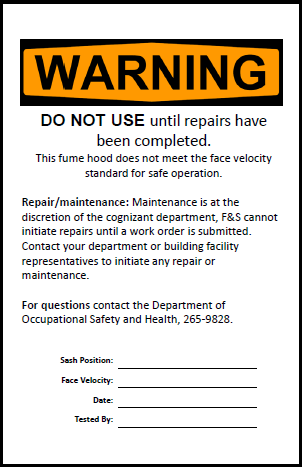

If the face velocity is outside the range listed on the Chemical Fume Hood Operating Parameters a WARNING sign willb e posted on teh sash and the previous year's green tag will be removed. If a WARNING sign is present, contact your facility manager for repair, OSH and DRS cannot initiate repair of failing hoods. Do not use hazarous material in the hood until it has been repaired and is working properly. The F&S Sheet Metal Shop will re-test the hood as part of the repair work. A copy of the WARNING sign is shown below in Figure 7.

Figure 7: WARNING sign indicating the face velocity was not within corresponding operating flow range.

The hood can function properly only if its integrity is not compromised. A hood with missing side panels or cracked sashes will not provide adequate exposure control.

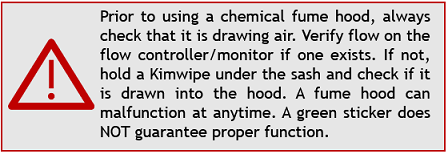

Because the status of the chemical fume hood can change anytime, continuous air flow indicators are recommended. New chemical fume hoods must be equipped with air flow monitoring devices which will alert the user if there is a problem with air flow. For older hoods without air flow monitoring devices, a simple visible test to ensure flow into chemical fume hoods and other ventilating devices is to tape a tissue to the hood and note its movement when the exhaust fan is turned on.

Safe Work Practices

To reduce the risk of exposure as much as possible, adhere to the following work practices:

- Open the sash or sashes only as much as is required to perform your work comfortably. Never open it beyond the indicated position when hazardous chemicals are present. Position the sash to maximize protective shielding.

- Verify that the chemical hood is drawing air. Check the flow monitor if present, or hold a Kimwipe in the hood and check its movement. Note: Do not let go of the wipe. Wipes sucked into the ductwork will block airflow and may cause damage requiring expensive repairs.

- Perform all work at least 6 inches into the hood and do not store items near the opening where they interrupt airflow and pose a spill hazard.

- NEVER put your head in the hood when hazardous chemicals are present.

- Do not position large equipment or containers of chemicals in the back of the hood where they block airflow. Elevate equipment by placing it on blocks, jack stands, or legs so that air can flow underneath to the bottom baffle slot. To store items in the back of the hood, install shelves to elevate containers (see Figure 8). Keep inside the hood only what needs to be there and remove everything that can be stored outside.

- Route service connections under the airfoil and secure all loose and dangling electrical cords, tubes and tubing with tie-raps, twist ties, or rubber bands.

- Discontinue work and close all containers with hazardous chemicals if the alarm sounds. If possible, mute the alarm, put an out-of-order sign on the hood, and contact your department business office to arrange for repair.

- When the hood is not in use, lower the sash. This will significantly reduce energy consumption and the sash will act as a shield in the event of an unexpected release.

- Ductless fume hoods are not recommended due to limitations on chemical use within the hoods and required maintenance. OSH and F&S do not provide support for ductless fume hoods. Verification of proper operation and maintenance/repair is solely the ersponsibility of the owning department.

Figure 8: A plank shelf allows chemical storage inside the hood while maintaining proper hood functioning.

Questions?

If you have questions about properly using chemicals in your fume hood or storing chemicals please emails DRS at drs@illinois.edu.

If you have questions about annual fume hood face velocity testing please email OSH at oshs@illinois.edu.

If your hood is not operating properly please contact yoru departmental facilitiy representative. If the interior of the hood or exhaust system must be accesssed to complete the repair your department will be asked to complete its responsibilities as described in the Lab Exhaust Maintenance SOP.