The University of Illinois at Urbana-Champaign has an established policy for emergency eyewashes and showers in the Campus Administrative Manual, Number RP-07. This Emergency Eyewash and Shower Program document was developed to assist campus units in understanding the requirements set forth by that policy. As stated in the campus policy, all reasonable efforts shall be made to meet the requirements specified in the most recent edition of the American National Standard for Emergency Eyewash and Shower Equipment (ANSI, Z358.1), which is an industry standard for the design, performance, installation, use, and maintenance of emergency eyewashes and showers.

Areas that Require Emergency Flushing Equipment

Suitable facilities for flushing or drenching of eyes and body must be provided within the work area where there is the potential for an exposure to the eyes or body with corrosive or injurious substances.

What is a corrosive substance?

Substances that cause visible destruction of or irreversible alterations in living tissue by chemical action at the site of contact are considered corrosive. Acidic materials with pH less than 4.0 or bases (alkaline) with pH greater than 9.0 are considered corrosive. Common corrosives include strong acids, strong bases, and concentrated solutions of weak acids or bases. There are other compounds that are corrosive to living tissues and are less obvious (Lewis acids, calcium oxide, concentrated hydrogen peroxide, sodium hypochlorite, acid anhydrides, alkylating agents, some organics, etc.). The container label and section 2 of a chemical’s Safety Data Sheet can be used to determine if a chemical is corrosive. Some substances may be classified as acids or bases but their actual level of corrosiveness is low when in contact with the body or eyes and would not be considered likely to cause injuries. These can include hand soaps and some food items like vinegar or lemon juice.

What is an injurious substance?

There are some materials that are not considered corrosive but require immediate flushing to prevent adverse effects to the health and safety of a person. For the purpose of this document, an injurious substance is one that is dangerous by eye or skin exposure. Materials that are absorbed through the skin and can cause additional harm to the body are captured here. For example, methylene chloride and many other organic compounds are classified as injurious by dermal exposure. Other hazards must be evaluated based on their risk of exposure and severity of the consequence (e.g., use of pyrophorics, use of DMSO as a carrier solvent). Potentially infectious materials are considered injurious and must be flushed immediately from eyes (mucous membranes).

What are suitable facilities?

The hazard of the material determines the suitability of the facility used for drenching a body part. See below for examples of emergency equipment and when they are required for corrosive or injurious materials.

Emergency eyewashes (or eye/face washes) are required in areas where there is a potential eye exposure. These areas include laboratories, chemical storage or mixing facilities, shops, and other areas where these hazardous materials are manipulated. Emergency eyewashes are also required in facilities working at Biosafety Level 2 (BSL2).

Emergency showers are required in areas where there is a potential for dermal exposure. These areas includes laboratories, chemical storage or mixing facilities, shops, and other areas where these hazardous materials are manipulated.

Drench hoses are supplemental units and do not replace the need for emergency showers or eyewashes.

Self-contained eyewashes are discouraged from being installed on campus in lieu of plumbed eyewashes. These units require a weekly visual inspection of the flushing fluid, replacement of the fluid cartridges when they expire, and the need to maintain additional cartridges. Before purchasing one of these units, contact DRS to determine if this is an appropriate option.

Still uncertain about what is required?

If the need for emergency equipment is not clear based on the above definitions, a risk assessment must be performed to determine the potential and severity of a consequence after exposure to the hazard. Contact DRS to help perform this risk assessment. Exceptions may be granted in cases where emergency equipment installation and use causes a more significant hazard than the chemicals present (e.g., rooms that have electrical hazards). In these cases, there still must be a means of flushing chemicals from the body and eyes in an adjacent location.

Maintaining Emergency Equipment

Annual testing

Plumed eyewashes, emergency showers, and supplemental drench hoses must be tested annually to ensure conformance with installation and operation guidelines in ANSI Z358.1. The testing is required to be performed by DRS. Results from annual testing are available to designated facility managers via the DRS website. Communication of testing results, including tagging, is outlined in Appendix A. Contact DRS at drs@illinois.edu or 333-2755 if you have questions on how to set up the annual test for your department.

Weekly Activation of Plumbed Eyewashes

In addition to annual testing, plumbed eyewashes must be activated weekly for a period long enough to verify operation and ensure that flushing fluid is available. This helps clean out any rust, scale deposits, or bacteria that may accumulate. This is the responsibility of the occupants of the space. The weekly activations should:

- Ensure that access to the eyewash is unobstructed.

- Visually inspect the eyewash to ensure that there are no broken parts, leakage etc.

- Verify that protective eyewash covers are properly positioned, clean and intact.

- Check that the spouts are clean, and the bowl and/or sink drains are free of trash.

- Check that the flow is effective and continuous.

- Maintain an activation log for this weekly inspection. Tags are available free of charge from DRS by calling 333-2755 or filling out our sticker and tag request form.

- Ensure that problems identified during the activation are resolved as soon as possible. If the unit is found to be non-operational, and there are no other units in the space as back-up, all work with hazardous material that require an eyewash must cease until the unit is repaired.

Periodic Activation of Emergency Showers

Logistics prevent most departments from performing weekly activations of emergency showers as specified in ANSI Z358.1. When activations are feasible, the periodic activations should:

- Ensure that access to the shower is unobstructed.

- Visually inspect the shower to ensure that there are no broken parts, leakage etc.

- Check that the flow is effective and continuous.

- Maintain an activation log for all activations. Tags are available free of charge from DRS by calling 333-2755 or filling out our sticker and tag request form.

- Ensure that problems identified during the activation are resolved as soon as possible. If the unit is found to be non-operational, and there are no other units in the space as back-up, all work with hazardous material that require a shower must cease until the unit is repaired.

Installing and updating emergency equipment

Emergency showers and plumbed or self-contained eyewashes must meet the following requirements of ANSI Z358.1 and the University of Illinois at Urbana-Champaign Facilities Standards (Appendix B).

- The equipment is certified by the manufacturer as meeting the most recent edition of ANSI Z358.1.

- The equipment has a controlled flow of flushing fluid that is provided to both eyes simultaneously (for eyewashes), which is not injurious to the user.

- Valves on emergency eyewashes and showers are designed so that the flushing fluid remains on without requiring the use of the operator’s hands. The valve is designed to remain activated until intentionally shut off.

- Emergency eyewash nozzles are protected from airborne contamination. Whatever means is used to afford such protection, its removal will not require a separate motion by the operator when activating the unit.

- The equipment is in unobstructed and accessible locations that require no more than 10 seconds for the injured person to reach along an unobstructed pathway from the source of the hazard. A door in the pathway is considered an obstruction and no new spaces requiring access to the units shall be designed with this obstruction.

- The equipment is located such that accessing the equipment should not require going up and down stairs or ramps.

- The equipment location is identified with a highly visible sign that contains graphical symbols to communicate across language barriers. Signs are white and green to comply with safety instruction and equipment location sign standards (ANSI Z535 Safety Alerting Standards-NEMA, 2011).

Specific Plumbed or Self-Contained Eyewash Requirements

- Eyewashes are installed so that they are capable of delivering to the eyes a minimum of 0.4 gpm (>3.0 gpm for eye/face washes) of flushing fluid for 15 minutes.

- Eyewashes are installed with the water nozzles 33-53 inches from the floor and 6 inches minimum from the wall or nearest obstruction. If they are installed mounted on a counter, they are mounted within 6 inches of the front edge of the lab sink (see Appendix B or drawing No. 15440 in the Facilities & Services (F&S) Facilities Standards) to allow the eyes to be placed in the path of water by simply standing near the unit. There is minimal reaching, bending, stretching or contorting required to reach the eyewash.

- All new plumbed eyewashes have a drain as per the Illinois State Plumbing Code, (most recent edition).

- Eyewashes are not to be installed on a faucet spout as per the Illinois State Plumbing Code, (most recent edition)

- Eyewashes are installed to meet ADA accommodations where required. ADA accommodations are always required in teaching and instructional spaces (including makerspaces) and in areas where a request for accommodation has been made for a qualified disability. The Office of Diversity, Equity, and Access (ODEA) can be contacted to request an accommodation. Contact Campus Code Compliance & Fire Safety for more information about ADA requirements and installation guidelines that are different from those listed above.

Specific Emergency Shower Requirements

- Emergency showers are installed so that they are capable of delivering a minimum of 20 gpm of flushing fluid for 15 minutes.

- Emergency shower heads are designed so that a flushing fluid column is provided not less than 82 inches and not more than 96 inches in height from the surface on which the user stands.

- The shower head is not mounted flush or recessed with any constructed surfaces or partitions, and the center of the spray pattern should be located at least 16 inches from any obstruction.

- The spray pattern shall have a minimum diameter of 20 inches at 60 inches above the surface on which the user stands.

- All new plumbed and self-contained emergency showers have a floor drain as per the Illinois State Plumbing Code, (most recent edition).

- The manual actuator (triangle pull) is not located more than 69 inches above the surface on which the user stands. The manual actuator is free from obstruction for 18 to 24 inches in most directions.

- Emergency showers are installed to meet ADA accommodations where required. ADA accommodations are always required in teaching and instructional spaces (including makerspaces) and in areas where a request for accommodation has been made for a qualified disability. The Office of Diversity, Equity, and Access (ODEA) can be contacted to request an accommodation. Contact Campus Code Compliance & Fire Safety for more information about ADA requirements and installation guidelines that are different from those listed above.

Reporting and Testing New Installations

New emergency equipment must be reported to DRS by facility managers after installation. The includes equipment installed by Facilities and Services and outside contractors. All new emergency equipment must meet the installation and operation guidelines in ANSI Z358.1. A full test to determine if it meets these guidelines must be performed after installation. Contact DRS to set up a time to perform this test.

Water Temperature

Tepid water must be supplied to emergency equipment. Water temperature from 60-100°F is considered tepid. Generally units without a mixing valve or tepid water loop will not maintain a temperature for 15 mins. This makes it difficult for a person to use the unit for the necessary length of time. Campus units should develop a plan to update older units so they have tepid water.

Units obstructed by doors

According to ANSI Z358.1, doors are obstructions in the path to emergency equipment. If buildings have their emergency equipment in the hallway or behind doors, a plan should be put in place to improve access to the equipment until it can be moved into the required rooms. Installing a closing mechanism that cannot be locked to impede access (i.e., panic hardware) to the equipment is one strategy for temporarily improving access to the equipment.

FAQs

Are personal eyewashes (squeeze bottles) able to be installed in lieu of suitable eyewash facilities?

Personal eyewashes do not meet the criteria of plumbed equipment. These units are only supplemental.

Where does the suitable eyewash/shower have to be located?

Emergency equipment must be readily accessible in areas where corrosive or injurious materials are used. They should be as close as possible to the area where a potential exposure can occur. At a maximum those work areas must be within 10 seconds of the emergency flushing equipment. ANSI defines the normal speed of travel as 55 ft per 10 seconds for an average person. Keep in mind that in an emergency, it may take longer than 10 seconds to travel this distance.

The route to the emergency equipment must be unobstructed. Doors are obstructions.

All the emergency showers are located in the hallway. What do I do?

Doors are obstructions in the path to the showers. It is important to improve accessibility to the emergency equipment. There must be a plan in place to improve accessibility to those units.

Does installation of a safety shower require a floor drain?

The Illinois Plumbing code requires that floor drains are installed. Section 890.800 Special Fixtures and/or Items Designed for a Particular Purpose. a) Emergency showers and eye wash stations within a building shall be provided with potable water and a trapped and vented receptor and shall comply with ANSI Z358.1.

Can I install an eyewash on a faucet?

The Illinois Plumbing code specifically states that this is not an option. Section 890.800 Special Fixtures and/or Items Designed for a Particular Purpose. b) Emergency eye wash stations shall not be installed on a faucet spout.

In addition to the information in the plumbing code, most facet mounted eyewashes cannot be turned on in one motion and there is a difficulty of setting a proper temperature that is not injurious to the eyes.

Who can install or modify eyewash and shower equipment?

Licensed Illinois plumbers must be used to modify and install equipment on campus.

Definitions

Combination unit – A unit that has a combination of an emergency shower and either an eyewash or eye/face wash.

Drench hose – A supplemental device consisting of a flexible hose connected to a flushing fluid supply and used to irrigate and flush face and body areas.

Emergency shower – A device specifically designed and intended to deliver flushing fluid in sufficient volume to cause that fluid to cascade over the entire body. Showers shall be capable of delivering flushing fluid at a minimum of 20 gallons per minute.

Personal eyewash – A supplemental device to plumbed or self-contained eyewashes, which can deliver immediate flushing fluid to the eyes or body. These do not replace the need for a plumbed or self-contained eyewash unit that meets the ANSI Z358.1 standard.

Plumbed eyewash – An eyewash unit permanently connected to a continual water supply that is capable of delivering a minimum of 0.4 gallons per minute (gpm) for 15 minutes to both eyes simultaneously at a velocity low enough to be non-injurious to the user.

Self-contained eyewash – A stand-alone eyewash device containing flushing fluid that is capable of delivering a minimum of 0.4 gpm for 15 minutes to both eyes simultaneously at a velocity low enough to be non-injurious to the user.

References

Occupational Safety and Health Regulation 29 CFR 1910.151(c):Medical Services and First Aid

American National Standards Institute (ANSI), Z358.1, most recent edition: Emergency Eyewash and Shower Equipment

Center for Disease Control and Prevention/National Institutes of Health: Biosafety in Microbiological and Biomedical Laboratories (most recent edition)

Illinois State Plumbing Code (most recent edition)

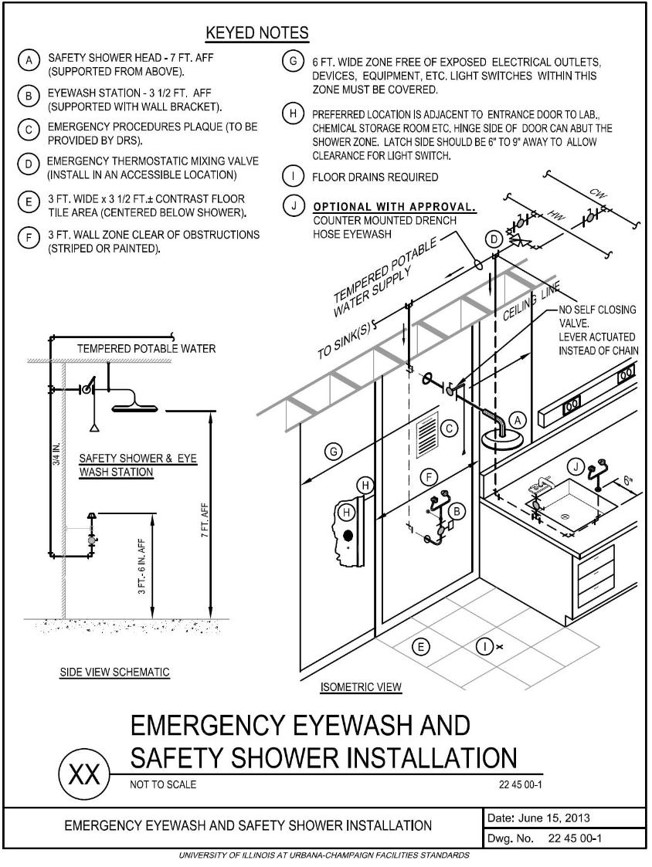

University of Illinois at Urbana-Champaign Facilities Standards (see "Building Elements: Laboratories, chemical and biological" and "Drawing 22 45 00-01")

Appendix A

Tagging for Annual Eyewash-Shower Testing

As part of the annual testing of emergency eyewashes and safety showers, the units are tagged with testing dates. To help delineate the annual test vs weekly activations, F&S plumbers and DRS have developed a new tagging approach that also indicates status.

PASS: A green tag indicates that the unit passed the test.

FAIL: A yellow tag indicates that the unit failed to meet one or more testing parameters, but is still operable. More information about the specific failure for each unit can be found on the DRS website via the eyewash/safety shower page.

INOPERABLE: If a unit fails (yellow tag) and is inoperable (i.e. cannot be used in case of an emergency), a red bag will be placed over the unit. All work with hazardous materials in the space must cease until the unit is repaired.

The building contact and occupants of the lab will be notified immediately when such a unit is found so a work order can be placed.

Appendix B

University of Illinois Facility Standard (Drawing 22-45-00-01)